Basic Info.

Model NO.

JY

Voltage

380V 50Hz 3 Phase (or as Needed)

Flow

2000-10000 Liters/8 Hours--10 Hours

Dimension

The Overall Dimension Depends on Filtering Area.

After Sale Service

Engineers Available to Service Machinery Overseas

Transportation Package

Spare Parts in Wooden Case

Transport Package

in Wooden Case

Specification

As required

Trademark

JOYE

Origin

Shanghai

HS Code

8421299090

Production Capacity

5000 Pieces Yearly

Product Description

Description

The JYYL oil-water separation filter,what Shanghai Junyi Filter Equipment Co.,Ltd, is a multi-stage filtration system.The whole system includes four grade filtration.Firstly,remove the impurity of particles.Then separate the water from the continuous liquid.Finally,oil-water separation by the separation filter element.

First grade pre-filtration system

Adsorption and filtration.The filtration accuracy is 1,000nm.

Second grade Fine filtration sytem

Sedimentation and filtration.The filtration accuracy is 100nm.

Third grade Ultrafiltration system

The filtration accuracy is 50nm.

Fourth grade Oil-water separation

Made from the imported material

Fifth grade Oil-water filtration

Made from the imported material

Technical Details 1.Suitable oil:Diesel,aviation kerosene,gas oil

2.Unsuitable oil:Emulsified diesel oil,diesel oil decolorization,water-containing diesel

3.Application:small oil depot,gas station,petrol station for transportation company,diesel used in the construction site or for the construction vehicles,generator,aviation kerosene,mine-owned diesel depot

4.Flow process:Multi stage filtration.It needs to change the consumption materials

5.Filtration precision:200--50nm ultrafiltration.98% impurities can be caught.

6.Filtering material:It needs to be cleaned and to be used again and again.

7.Pressure monitoring:Automatic pressure monitoring device to monitor the filtration pressure any time to avoid overload operation of the feeding pump.

8.Filtration pressure:0.2-0.3Mpa/low pressure filtration,stable flow rate,stable

filtration effect.The filtered oil is clear and transparent.

9.Power:380V/50HZ

Function & Advantage

1.Filtering the suspended particles such as the impurities,resin ,asphalt,sulfur or phosphorous in the diesel to improve the diesel quality and protect the injection system.

2.Saving fuel

3.Reducing exhaust emissions.

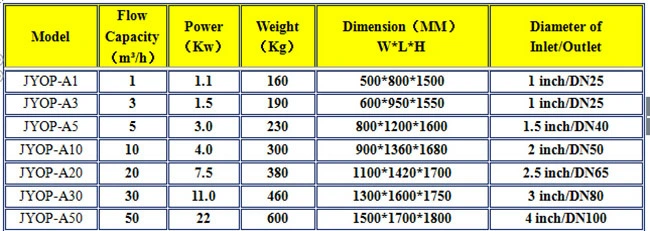

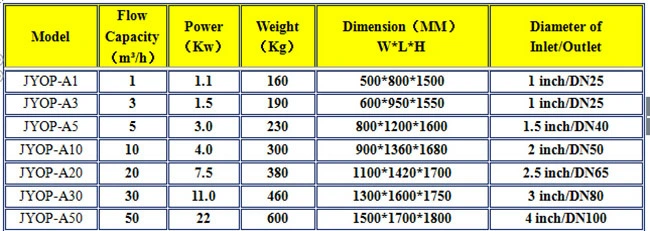

Technical Paramter of Diesel Filter System

Working Site of Diesel Filter System

Final Usage of the Filtered Diesel

Our service

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer's requirements.

After-sale service

Provide considerate services to minimize clients' worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Warm notice

In order to quote you the right vertical pressure Vegetable oil leaf filter / oil leaf filter with best price, we would like to get the following information included in your inquiry:

1.What is the raw materiral?

Material related characteristic?Does it corrsive,strong basicity or highly acid?Please confirm.

2.What is the capacity per hour you need (kg/h)?

3.What is the initial moisture and final moisture of finished products your require to get?

4.What about the maximum heat temperature of raw material?

5.What kind of fuel you use to heat the dryer?Natural gas,electricity,fuel oil or steam?

6.Which equipment material do you like prefer?SUS304, SUS316L or Carbon steel?

7.Provide us your country's electricity information, such as phases, voltage, HZ?

8.How about dust collect requirements?

9.Other special requirements?

Packing & Shipping

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Spare parts, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Contact Us

The JYYL oil-water separation filter,what Shanghai Junyi Filter Equipment Co.,Ltd, is a multi-stage filtration system.The whole system includes four grade filtration.Firstly,remove the impurity of particles.Then separate the water from the continuous liquid.Finally,oil-water separation by the separation filter element.

First grade pre-filtration system

Adsorption and filtration.The filtration accuracy is 1,000nm.

Second grade Fine filtration sytem

Sedimentation and filtration.The filtration accuracy is 100nm.

Third grade Ultrafiltration system

The filtration accuracy is 50nm.

Fourth grade Oil-water separation

Made from the imported material

Fifth grade Oil-water filtration

Made from the imported material

Technical Details 1.Suitable oil:Diesel,aviation kerosene,gas oil

2.Unsuitable oil:Emulsified diesel oil,diesel oil decolorization,water-containing diesel

3.Application:small oil depot,gas station,petrol station for transportation company,diesel used in the construction site or for the construction vehicles,generator,aviation kerosene,mine-owned diesel depot

4.Flow process:Multi stage filtration.It needs to change the consumption materials

5.Filtration precision:200--50nm ultrafiltration.98% impurities can be caught.

6.Filtering material:It needs to be cleaned and to be used again and again.

7.Pressure monitoring:Automatic pressure monitoring device to monitor the filtration pressure any time to avoid overload operation of the feeding pump.

8.Filtration pressure:0.2-0.3Mpa/low pressure filtration,stable flow rate,stable

filtration effect.The filtered oil is clear and transparent.

9.Power:380V/50HZ

Function & Advantage

1.Filtering the suspended particles such as the impurities,resin ,asphalt,sulfur or phosphorous in the diesel to improve the diesel quality and protect the injection system.

2.Saving fuel

3.Reducing exhaust emissions.

Technical Paramter of Diesel Filter System

Working Site of Diesel Filter System

Final Usage of the Filtered Diesel

Our service

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer's requirements.

After-sale service

Provide considerate services to minimize clients' worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Warm notice

In order to quote you the right vertical pressure Vegetable oil leaf filter / oil leaf filter with best price, we would like to get the following information included in your inquiry:

1.What is the raw materiral?

Material related characteristic?Does it corrsive,strong basicity or highly acid?Please confirm.

2.What is the capacity per hour you need (kg/h)?

3.What is the initial moisture and final moisture of finished products your require to get?

4.What about the maximum heat temperature of raw material?

5.What kind of fuel you use to heat the dryer?Natural gas,electricity,fuel oil or steam?

6.Which equipment material do you like prefer?SUS304, SUS316L or Carbon steel?

7.Provide us your country's electricity information, such as phases, voltage, HZ?

8.How about dust collect requirements?

9.Other special requirements?

Packing & Shipping

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Spare parts, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Contact Us